Wednesday, May 7, 2014 1:00 PM (ET), Scandia Mfg. Co.

Information

VIEW LOT CATALOG

Due to the Complete Plant Closure of Scandia Mfg. Co., Inc., CNC Manufacturing Company, Including: CNC Turning Centers, CNC Machining Centers, Machine Tools, Inspection Equipment, Plant Support Equipment, etc.

Baltimore, Maryland - USA

FEATURED ITEMS

(New 1998) Mori-Seiki # SL-300B-700 CNC Turning Center, W/ 12" Hyd. 3- Jaw Chuck, Swing Over Bed 28.1”, Swing Over Crosslide 19.7”, Center Dist. 27.55”, Spindle #A-2-8, Spindle Bore 4.1”, 25-2500 RPM, Tail Stock Quill # 5-MT, (10) Pos.Turret w/ Tooling, Tailstock, 40 HP, Coolant System, Chip Conveyor & MORI-FANUC # MSC-501 CNC Controls, S/N 436

(New 2000) Mori-Seiki # SL-253B-500 CNC Turning Center, W/ 10" Hyd. 3-Jaw Chuck, Swing Over Bed 26.7”, Swing Over Crosslide 20.1”, Center Dist. 22.6”, Spindle #A-2-8, Spindle Bore 3.4”, 35-3500 RPM, Tail Stock Quill # 5-MT, (10) Pos.Turret w/ Tooling, Tailstock, 20 HP, Coolant System, Chip Conveyor & MORI-FANUC # MSC-600 “MAPPS” CNC Control, S/N 2106

(New 1985) Mori-Seiki # SL-3H CNC Turning Center, W/ 8" Hyd. 3-Jaw Chuck, Swing Over Bed 22.4”, Swing Over Crosslide 16.1”, Center Dist. 24”, Spindle #A-2-6, Spindle Bore 3.03”, 35-4000 RPM, Tailstock with # 3-MT Quill, (12) Pos.Turret w/ Tooling, 20 HP, Coolant System, Chip Conveyor & FANUC # 11-TB CNC Control, S/N 4170

(New 2005) Mori-Seiki # DURACENTER-5 CNC Vertical Machining Center, W/ Table Size: 43.3”x 23.6”, Max. Load Cap. 1760 lbs., Travels: 31.5”-X, 20.1”-Y, 20.1”-Z, (20) Pos. Auto-Toolchanger, Spindle RPM 12,000, CAT # 40, 20 HP, Rapid Feed Rates 944 IPM all Axis’s, Coolant System, Full Enclosure & FANUC-MORI # MSX-501 “MAPPS” CNC Control, S/N DC005DK0145

(New 2001) Mori-Seiki # SV-503B-50 CNC Vertical Machining Center, W/ Table Size: 52”x 23.6”, Max. Load Cap. 2640 lbs., Travels: 40.2”-X, 20.1”-Y, 20.1”-Z, (30) Pos. Auto-Toolchanger, Spindle RPM 10,000, CAT # 50, 30 HP, Rapid Feed Rates: 1653 IPM all Axis’s, Thru-Spindle Coolant with Chip Blaster High Pressure Coolant System, Full Enclosure & FANUC-MORI # MSG-501 “MAPPS” CNC Control, S/N 2300

(New 2000) MAZAK # VTC-200B CNC Vertical Machining Center, W/ Table Size: 57.4”x 20.8”, Max. Load Cap. 2640 lbs., Travels: 44.1”-X, 21”-Y, 21”-Z, (24) Pos. Auto-Toolchanger, Spindle RPM 60-10,000, CAT # 40, 20 HP, Rapid Feed Rates: 1181 IPM all Axis’s, Auto Tool Length Comp., Coolant System, Full Enclosure & MAZAK Mazatrol-640M Fusion CNC Control , S/N 150379

(New 1985) Leblond-Makino # FNC-106 CNC Vertical Machining Center, W/ Table Size: 55.12”x 23.62”, Max. Load Cap. 3300 lbs., Travels: 41.3”-Y, 23.6”-Y, 22”-Z, (30) Pos. Auto-Toolchanger, Spindle RPM 10-3,500, CAT # 50, 20 HP, Rapid Feed Rates: 480 IPM all Axis’s, Coolant System, Full Enclosure & FANUC OM-B CNC Control, S/N LM-370

* TSUDAKOMA # RNCM-301R (12”) CNC 4th-Axis ROTARY Table W/ Tailstock

Bridgeport 4 HP Series II “Special” Vertical Milling Machine, W/ 11" X 60" Table, 1.5 HP Auxiliary Bridgeport Milling Head, Acu-Rite DRO, S/N 858

(7) Bridgeport 1 HP Vertical Milling Machines

Cincinnati “Heavy Duty” Production Horizontal Miller, W/ 26”x 130” Table, Dyna-Poise Over-Arm, #50 Taper Spindle & Universal Head, S/N 6B6BP5HE-1

Cincinnati # 4 “Universal” Horizontal Miller W/ 17”x78” Table & Vert. Head, S/N 4A4P2K-105

Monarch # 25N “Heavy Duty” Engine Lathe, W/ 33.5" X 288" (24’) Cap., W/ (2) Carriages, 18” 4-Jaw Chuck, Steady Rest & Follow Rest, Tailstock, Trav-A-Dial, & Hydraulic Tracer, S/N 34863

Monarch # 10EE “Precision” Toolroom Lathe, Swing over Bed 12-1/2", Swing over Cross-Slide 7-1/4", Center Swing over Bed 12-1/2" Swing over Cross-Slide 7-1/4" Distance between Centers 20", Spindle Bore 1.4", Spindle Speeds 0 - 4000 RPM Variable, D-1-3 Camlock Spindle Bore 1.4" ,S/N 45759

Hardinge # DV-59 Secondary Lathe, W/ Turret

Hardinge # HSL-5C Speed Lathe, W/ Collet Closer, S/N HSL-5C-1136D

(New 2010) KALAMAZOO # MS-1318-SA “Miter Type” Metal Cutting Band Saw

(New 2006) (2) SULLAIR # ES-6 “Rotary Screw” 10 HP Air Compressors

(New 2006) AIRTEK # SC-130 Air Dryer, W/ Digital Controls, S/N 10E-D09717

MITUTOYO # B-231 Coordinate Measuring Machine W/ Renishaw Probe, Dell Computer w/ Monitor & Updated Software

(New 2008) Deltronic # DH-214 Optical Comparator W/ Angular Table, Surface Reflection, Deltronic # 612-R DRO, S/N 229082916

(New 2006) Brown & Sharpe “Tesa” Digital Hite-Gage, S/N 7D-006-02

Yale # GLC-050 Forklift w/ 5000 lb. Cap., 192” Lift Cap., LPG, Solid Tires &Triple Mast

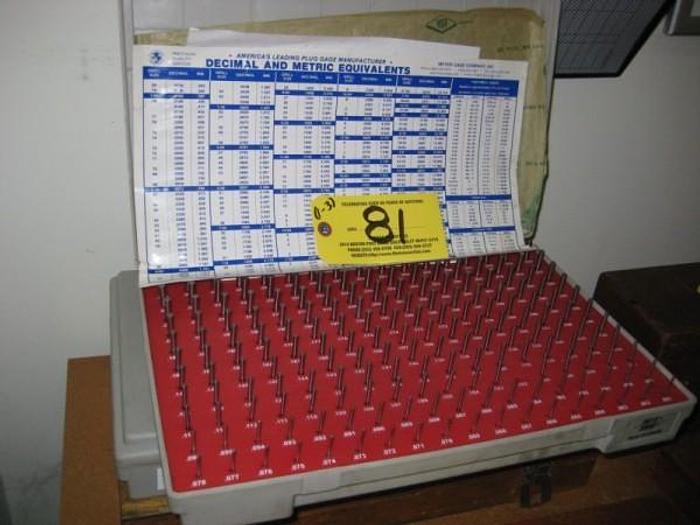

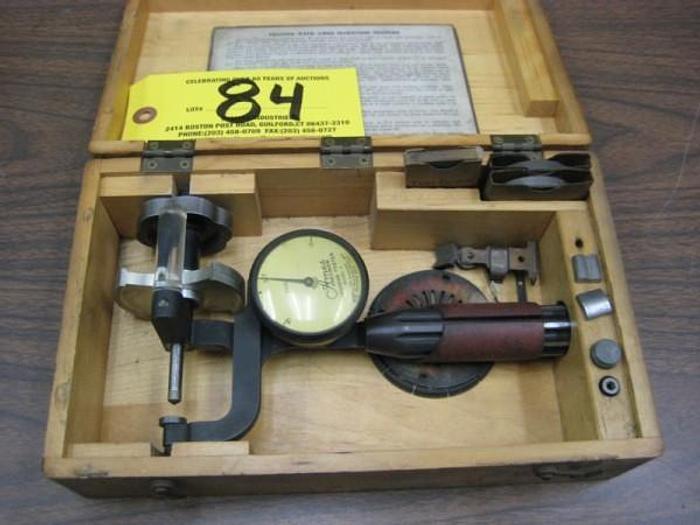

Inspection Equipment including: Mitutoyo CMM, Rockwell-Wilson Hardness Tester, Portable Hardness Testers, Optical Comparator, Granite Surface Plates, Thread Gages, Intra-Mikes, Disc Micrometers, Thread Micrometers, Mitutoyo Digital Verniers, Surface Finish Gages, Mitutoyo Surf-Test, MAHR Surf-Test, Precision Levels, Thread Ring & Plug Gages, Micrometers, Depth Gages, Dial Bore Gages, Calipers, Gage Blocks, Microscope, TESA Electronic Gages, Verniers, Pin Gauges, etc.

Tooling & Equipment including: KURT Vises, (100+) # 40 & # 50 CAT CNC Toolholders, BIG Shepard CNC Right Angle Head, Right Angle Plates, (3) Aloris Toolposts, Chucks, Drills, End Mills, Magnetic Chucks, 5C Collet Indexers, CNC Type Knurling Tools, Carbide Inserts, Carbide Boring Bars, Carbide Insert, CNC Lathe Tools, Sunnen Hone Tooling, K.O. Lee 5C Motorized Workhead, Boring Bars, Drills, Collets, Chucks, Ring Gages, Thread Gages, Wheel Dressers, Diamond Wheels, etc.

Misc. Plant Support & Machinery including: Shop Fans, Digital Scale, Portable Electro- Magnetic Drill, Shop Carts, NOVA Vibratory Finish Machine, Lyon Metal Shelving, Raw Material Racks, Work Benches, Shop Chairs, Wet Vacuum, Acetylene Torch Carts, Welders, Double End Grinders, Raw Material, Scrap Metal, Drill Presses, Di-Acro Notcher & Bender, Famco # 3.5 Arbor Press, Pallet Jack, Engine Hoists, Baldor 2" Belt Sander, Rockwell 6” Belt Sander, Paint Booth, VIDMAR Tool Cabinets & Work Benches, etc.

Much More!! See Lot Catalog For Complete Listing!!

RIGGING & SHIPPING

Buyer's are fully responsible for all rigging and transportation costs. Please get rigging quotes prior to bidding and bid accordingly.

SHIPPING & RIGGING QUOTES:

Pedowitz Machinery Movers - Andy Conti

P: 203-877-7458 Email: andy@pedowitz.com

PROJECT SPECIFIC TERMS & CONDITIONS

Buyer's Premium: 15%

Staggered Closing Times: Lots Have 60-Second Staggered Closing Times.

Auto Extend Bidding: If a bid is submitted with less than 3-minutes remaining, the closing time for that lot will be extended by 3-minutes.

Payment Due In Full: Friday, May 9, 2014

Payment Types: Cash, Certified Check or Wire Transfer

Removal: Final Date For Removal is Friday, May 16, 2014. NO EXCEPTIONS

Buyers are fully responsible for all removal of purchases. Please get removal quotes prior to bidding and bid accordingly. Buyers of the printing presses will have an additional week for removal

All bids constitute a legally binding contract and bidders will be legally obligated to make payment and remove items in accordance with the terms and conditions of the sale.

Details

| Equipment Location | Scandia Mfg. Co. 480 Brunswick Street Baltimore, Maryland 21223 USA |

| Auction Type | Online Auction - Internet Bidding Only |

| Auction Date | Wednesday, May 7, 2014, 1:00 PM (ET) |

| Inspection | Tuesday, May 6 (9 am to 5 pm) |